G-en en en en ence n300v5-the the part partnsit

Tilmaanta ugu weyn ee wax soo saarka

| Awood wax soo saarka (W) | Soo-jeedinta lagu qiimeeyay Maanyo danab (Banaan) | Wax soo saarka lagu qiimeeyay Vattage (VDC) | Wax soo saarka Seere daaq (A) | Sax | Casiiyay iyo Buuq (mvp-p) |

| 300 | 200-240 | +5.0 | 0-60.0 | ± 2% | ≤50 |

Xaaladda deegaanka

| Wax | Cayimid | Cutub | Qorid |

| Heerkulka shaqada | -30 +60 | ℃ |

|

| Heerkulka kaydinta | -40 ~ +80 | ℃ |

|

| Qoyaan qaraabo ah | 10 ~ 60 | % |

|

| Nooca qaboojinta | Is-qaboojinta |

|

|

| Cadaadiska jawiga | 80 ~ 106 | KPA |

|

| Dhererka ka sarreeya heerka badda | 2000 | m |

Dabeecad koronto

1) astaamaha galka

| NO | Wax | Cayimid | Cutub | Qorid |

| 1.1 | Korantada galka | 200 ~ 240 | Eeg |

|

| 1.2 | Soo noqnoqoshada soo-noqnoqda | 47 ~ 63 | Hz |

|

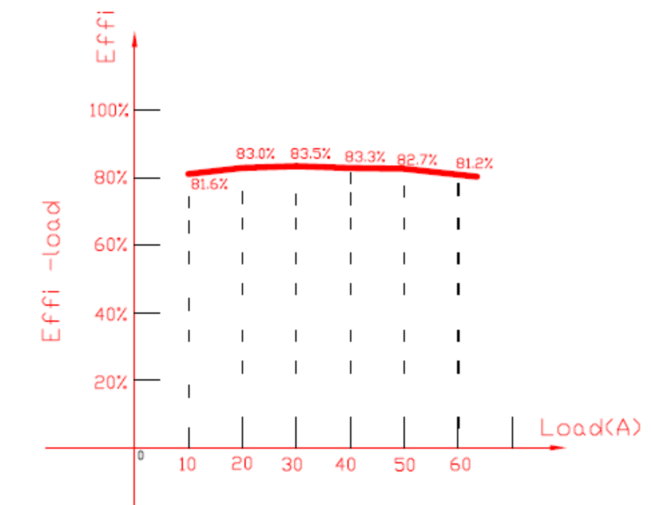

| 1.3 | Aflimiin ah | ≥80 (vin = 220vac) | % | Wax soosaarka culeyska buuxa ee heerkulka caadiga ah |

| 1.5 | Awoodda Awoodda | ≥0.52 |

| Soosaarka culeyska buuxa ee korantada lagu qiimeeyay |

| 1.6 | Max | ≤3.0 | A |

|

| 1.7 | Bilaabidda Surge hadda | ≤60 | A | Imtixaanka Gobolka qabow |

2) astaamaha wax soo saarka

| NO | Wax | Cayimid | Cutub | Qorid |

| 2.1 | Qiimee korantada | +5 | VDC |

|

| 2.2 | Wax soo saarka | 0 ~ 60.0 | A |

|

| 2.3 | Kororka korantada adag ee adag | 4.6 ~ 5.4 | VDC |

|

| 2.4 | Heerka Qaanuunka Qaranka | ± 1% | Vo | Dhanka kale tijaabada culeyska iftiinka, culayska badh, culeys buuxa oo aan isku qasin |

| 2.5 | Heerka Xeerka Xeerka | ± 1% | Vo | |

| 2.6 | Xaqiijinta Xeerka Qaanuunka Korantada | ± 2% | Vo | |

| 2.7 | Dhawaaqa & dhawaqa | ≤50 | mvp-p | Soo-gelinta lagu qiimeeyay, wax soo saarka buuxa, 20mhz bandwidth, 47μf dacisitors oo is barbar dhigaya dhamaadka |

| 2.8 | Dib-u-dhigga Soo-Saar | ≤3000 | ms |

|

| 2.9 | Wax soo saarka waqtiga | ≥10 | ms | Vin = 220vac Tijaabada |

| 2.1 | Soosaarka korantada korantada | ≤50 | ms |

|

| 2.11 | Beddelka dusha sare | ± 5% | Vo | Xaaladda Tijaabada: Load buuxa, MODE CR |

| 2.12 | Soosaarka firfircoon | Isbedelka korantada ee ka yar + 5% vo; jawaabta jawaabta firfircoon ee waqtiga | Vo | Xamuul 25% -50%, 50% -75% |

3) astaamaha ilaalinta

| NO | Wax | Cayimid | Cutub | Qorid |

| 3.1 | Galitaan kahortaga korantada | 140 ~ 175 | Eeg | Xaaladda Imtixaanka: Load buuxa |

| 3.2 | Ka soo gal Pottage Ilaalinta Volt | 160-180 | Eeg | |

| 3.2 | Wax soo saarka wax soo saarka Ilaalinta | 66-90 | A | Hi-Cup Burp ka soo kabashada, ka fogaanshaha awooda waxyeelada muddo dheer kadib wareegga gaagaaban |

| 3.3 | Soosaarista barta Ilaalinta wareegga wareega | > 60.0 | A |

Xusuusin: Mar kasta oo ilaalin dhacdo, nidaam xiran. Marka korantada uu soo kabashada korantada, ka jar ugu yaraan 2 sekan, ka dibna saar, dib u soo celinta korantada.

4) astaamo kale

| NO | Wax | Cayimid | Cutub | Qorid |

| 4.1 | Mtbf | ≥40,000 | H |

|

| 4.2 | Bixinta hadda jirta | <1.0ma (vin = 220vac) | GB8898-2001 9.1.1 Qaabka Imtixaanka | |

Astaamaha amniga

| Wax | Sifo | Tech The The | Tacliiq | |

| 1 | Xoog koronto | Soo-saarista wax soo saarka | 3000vac / 10ma / 1min | Majiraan wax daboola, oo burburinna |

| 2 | Xoog koronto | Gelinta dhulka | 1500vac / 10ma / 1min | Majiraan wax daboola, oo burburinna |

| 3 | Xoog koronto | Wax soo saarka dhulka | 500vac / 10ma / 1min | Majiraan wax daboola, oo burburinna |

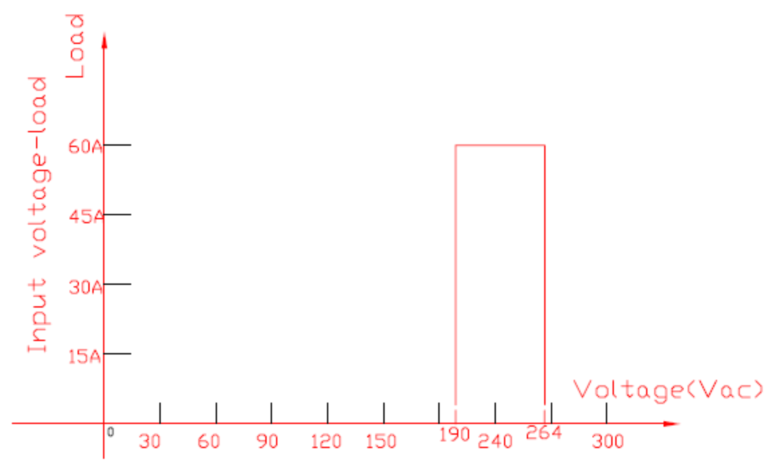

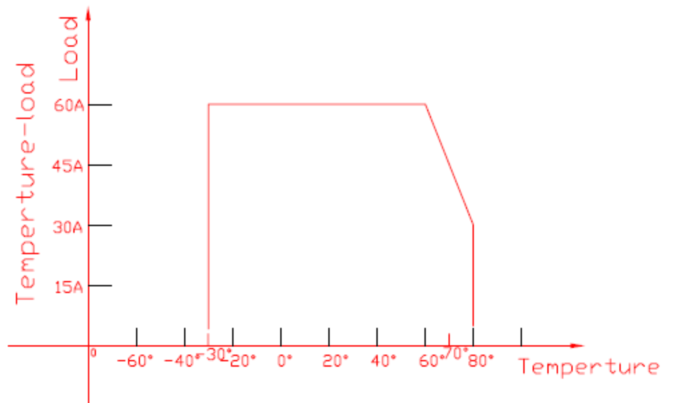

Qalooca xogta qaraabada

Korantada galka vs rar curyo

Heerkulka vs xawaashka

Hufnaanta vs xawaash

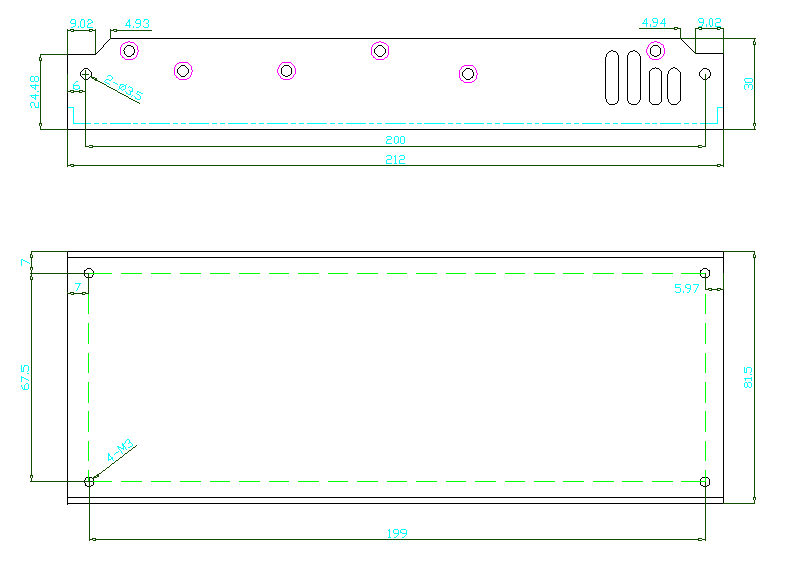

Astaamaha farsamada & Qeexitaanka Xiriirinta (Cutub: mm)

1) Cabbir jidheed l * w * h = 212 × 81.5 × 30.5 ± 0.5

2) Cabbirka goynta rakibaadda

Xusuusin:

XUQUUQDA XUQUUQDA XUQUUQDAADA waa M3, wadarta6. Boorarka go'an ee korantada ma ka badnaan karaan 3.5mm.

Ogeysiis Isticmaal ah oo Nabdoon

1) Rakibaadda, awooddu waa inay ahaato mid nabdoon oo qasab ah, fogaan aamin ah oo loogu talagalay jirridda birta ee dhinac kasta waa inay ahaadaan ≧ 8mm. Haddii ay ka yar tahay 8mm, dhumucda qashinka pvc ≧ 1mm waxaa looga baahan yahay in lagu xoojiyo dahaarka.

2) Tooska taabashada tooska ah ee saxafiga qaboojinta gacanta waa mamnuuc.

3) Dhexroor Bolt waa ≦ 8mm markii ay rakibayaan saxanka PCB.

4) Wuxuu ubaahanyahay sariir banaanka l285mm * w130mm * h3mm aluminium sidii wax lagu dhejiyo